Baby Diaper Production Line with Servo Drive

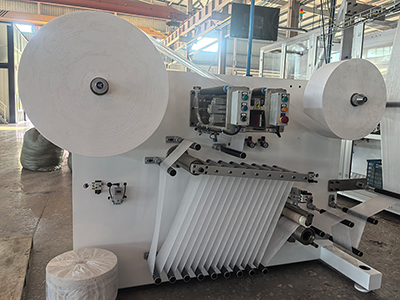

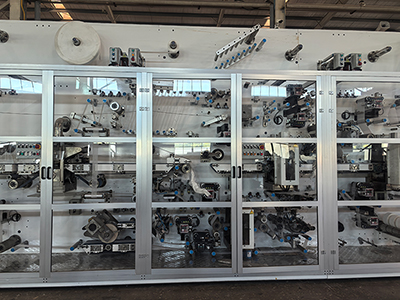

The fully servo baby diaper production line is a highly automated manufacturing solution designed for producing various types of baby diapers, including regular, large-waist, and T-shaped diapers. This diaper production line with servo drive features high efficiency, stability, and a low waste rate, making it ideal for large-scale production. With an impressive production speed of 500-700 pieces per minute and full-speed automatic material changeover without stopping, it ensures smooth and continuous operation.

| Power supply | 3 Phase, 380V, 50Hz |

| Power | About 420kW (excluding hot melt applicator and compressor) |

| Production speed | 500-700PPM |

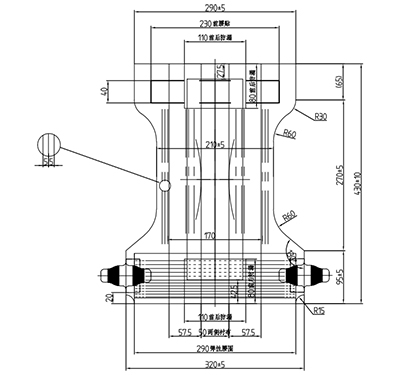

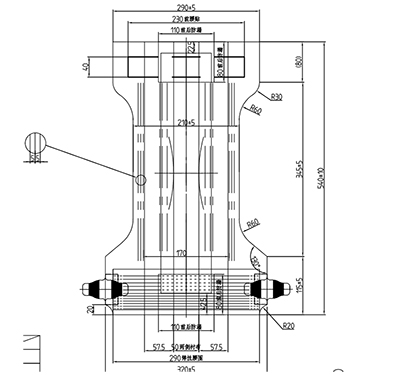

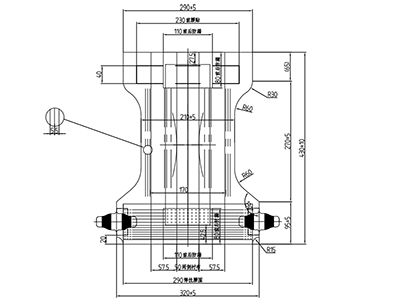

| Machine dimensions | 35*9*5m(L*W*H) (for reference) |

| Qualification | ≥97% |

| Air supply | 0.6-0.8Mpa |

- Compatible with both pulp-SAP mix and composite absorbent core

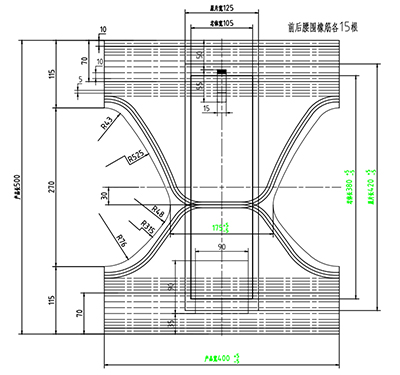

- High-density ultra-thin absorbent core forming system, offering excellent absorbency and low backflow

- Equipped with a web guiding system for precise material control

- Online S cut side tape without generating waste

- Fully servo-driven with a PLC control system for precise and efficient operation

- One-click specification switching for quick adjustments, reducing waste during model changes

- High-precision tension control system with automatic unwind and material splice detection

- Material splicing tail waste is minimized to just 3 meters, reducing material waste

- Fully automatic material detection with alarm systems for breakage and missing components

- Precise pattern positioning before application

- I-MAS intelligent equipment management and analysis system for optimal performance

- 3D fabric online production

- Laminated core online production

- Ultrasonic lamination of three-piece fabric

- Packaging or stacking machine

- Dust collection system for a cleaner working environment

Gachn is a professional counting stacking sanitary pad machine manufacturer and supplier, leader in designing and manufacturing automated bag packaging equipment. There are wide range of plastic bag packaging machines for packing disposable sanitary and facial tissue products. Gachn is a joint stock company contributed to providing quality disposable sanitary napkin bagging machines and custom packaging solutions for customers.