Automatic Case Erector

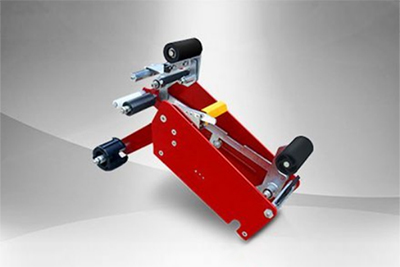

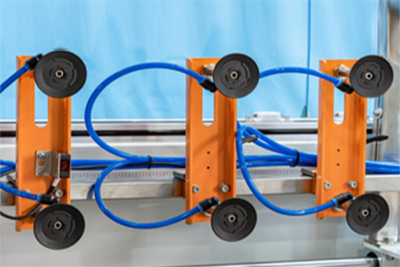

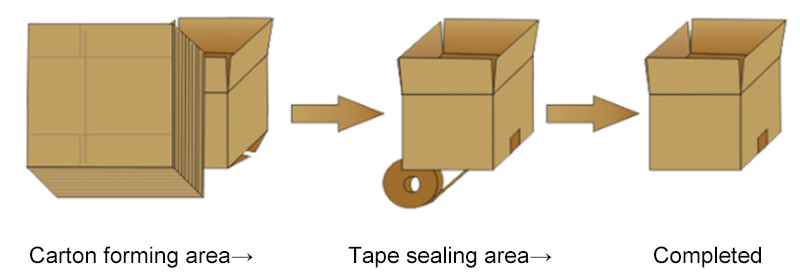

The fully automatic case erector is a key component of modern packaging lines. Driven by a servo system and PLC control, it efficiently performs carton opening, forming, bottom folding, and sealing. Built with a durable 304 stainless steel frame, the case erecting machine is equipped with high-precision suction devices and a vacuum conveyor belt, handling 8–10 cartons per minute. Its user-friendly touchscreen interface allows quick adjustment of speed parameters and incorporates smart functions such as material shortage alarms and automatic counting. Featuring a compact design, the case erector integrates seamlessly with case packers and palletizers, enhancing overall packaging line efficiency by over 30%. It is widely applied across industries including food & beverage, medical, and consumer goods.

| Power Supply | 220V 50/60Hz 1 phase |

| Power | 240W |

| Speed | 8-10 cases/min |

| Case Storage Capacity | 80-100pcs (1000mm) |

| Table Height | 620-670mm |

| Machine Dimension | L: 2350mm W: 2100mm H: 1650mm |

| Machine Weight | 600kg |

| Air Supply | 6kg/cm³ |

| Air Consumption | 450NL/min |

| Carton Size | L: 320-650mm W: 150-500mm H: 150-500mm |

| Tape Size | 48/65-72mm (choose one) 2inch, 3inch |

| Conveyor Belt Speed | 18m/min |

- The automatic case erector features a compact design with a vertical cardboard magazine, allowing for continuous replenishment without halting the machine to ensure uninterrupted operation and reduce labor costs. The bottom sealing machine features a well-engineered design, integrating synchronized suction and forming with automatic bottom folding and sealing in a single step. It delivers stable carton opening, faster operation, and higher overall efficiency.

- Fully automatic case erection machine features a glue leakage alarm and a transparent acrylic protective cover, minimizing any risk of operational accidents.

- The case erector is designed for seamless integration with upstream and downstream equipment, such as sealing machines and palletizers, to reduce the transfer time and manual errors effectively.

Gachn is a professional single pack wet wipe packaging machine manufacturer and supplier, leader in designing and manufacturing automated bag packaging equipment. There are wide range of plastic bag packaging machines for packing disposable sanitary and facial tissue products, applied for PE film packaging, OPP film packaging, PET laminated film packaging, aluminum coated film packaging, etc. Gachn is a joint stock company contributed to providing quality non-woven wet wipe bagging machines and custom packaging solutions for customers.